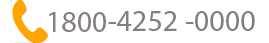

JAR WASHING FILLING & CAPPING (PC/PET-5 GALLON /6 GALLON BOTTLES)

Canadian Clear is one of the members of Canadian Group of Companies. Canadian Clear incorporates state of art technology in design engineering of the system being manufactured.

The CC 1000 PLC series consisting of 1 BPM to 25 BPM range has been specially designed and manufactured for 10 to 25 liters polycarbonate / Pet. Bottles are fed to bottle holders, which tilt the bottle on top of high pressure spray which washes the bottle in 3 stages. In the first stage the bottles are cleaned with hot water detergent (temperature ranging from 55 0 C to 80 0 C).

In the second and third stage the bottles are cleaned with ozone rise water with a concentration of 0.4 to 1 ppm of ozone. The machine has Angular Spray for external wash of the bottle. After the cleaning stage the bottles are put on the filling conveyor. The filling is executed by a highly sensitive sensor activating a flow of water to the accurate predetermined measured quantity.

AUTO LOADER

Empty Jars / Bottles are loaded through the Fully Automatic bottle loading system – Auto Loader from in-feed conveyor to bottle holder. An advanced Robot pneumatic system combined with optical sensor makes the loading process reliable and efficient.

SCRUBBER / JET SPRAY NOZZLE

Specially designed Nylo - Brussel Scrubber / Jet Spray Nozzles provided in combination with angular sprays to wash the Inner and Outer surface of the bottle. The Scrubber or Spray Nozzle is so designed even to clean the external neck area.

AUTOMATIC FILLING VALVES

Stainless steel sanitary high accuracy filling valve are used to achieve even filling in all bottles. Specially designed high pressure and low pressure filling cycle is provided with PLC Control.

CONTROL PANEL

State of art PLC is used with LCD display screen to ensure the machine. This system control important functions like Wash Time. Fill Time and Conveyor ON / OFF Time and also provide detailed fault detection features.

CLEAN ROOM SYSTEM

Built in Clean Room features with HEPA sub micron filter can be provided on request and extra cost.

FILLING HEADS

Stainless steel descending filling heads is provided to ensure highest sanitary filling without air bubble formation and water spillage.

CAPPING SYSTEM

Angular Counter Conveyer ensures proper stamping of the cap on to the Bottle neck. The caps are fed to the bottle neck by bottle sorter and efficient chute system.

Toll Free

Toll Free